My program can design and build most gears - spur, helical, bevel, chain sprockets ect. However most of my preparation work to ANSYS and ADAMS is done in Autocad 12 Dos - 2014 using my Lisp-C program I written for use in Autocad. My full dynamic simulation tool of choice is ADAMS. The Inventor has no problem in assembling the gears with surface interference and performing a simulation.

The Dynamic simulation has a different meaning in MSC ADAMS.

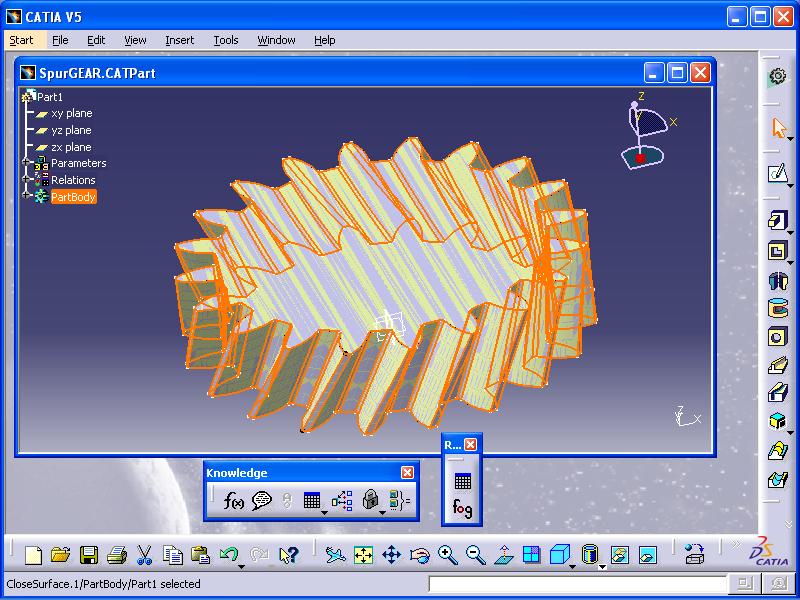

This is a pseudo "Dynamic simulation" component of Inventor 2014. Here is a brief description of our gear pear design and manufacture using our older software and Inventor 2014.įigure 02. We needed to go down the path of assembly software as our projects in helicopter and comb making required serious part trees that could be altered easily. This problem arises as we are more and more direct printing our 3D CAD files from our assembly components files *.ipt. Perhaps even in Solidworks an autodesk competitor ). It turned out that 3DP serious problem was with Autodesk software - Inventor 2014 Pro - perhaps fixed in later versions? ( it could also be in other Autodesk products that auto-gen gears.

In last year making prototypes containing gears generated straight from CAD to part using 3DP - it was considered a serious problem warranting an investigation ( we spent 2 months tracking the problem ). Our path to a prototype takes two main path - 3DP and/or CNC ( or combination of both ). In my company we design 3D CAD models, software and finally we manufacture the prototypes (depending on how much client wants to spend, after all software, computers and machines do not come cheap ). I have perhaps over simplified the relationship but it is a beginning of understanding the differences. The 3D CAD people are all about user interface and mathematics of solids depicted. The 3DP is a about studying the material strength, the delivery of the extruded material, layer cohesion ( ie delamination), 3DP machine design and software. Most user fall in two camps those shouting the virtue of 3DP and salvation of the known manufacturing world and 3D CAD users that worry about correct depiction of the object designed. The advantage of 3DP printing has always been the direct CAD to Physical Object path.

0 kommentar(er)

0 kommentar(er)